EPJ E Highlight - Modelling wrinkling and buckling in materials that form the basis of flexible electronics

- Details

- Published on 20 April 2020

As the demand for flexible electronics grows, researchers must develop robust models of how the materials that comprise them behave under stress.

Flexible circuits have become a highly desirable commodity in modern technology, with applications in biotechnology, electronics, monitors and screens, being of particular importance. A new paper authored by John F. Niven, Department of Physics & Astronomy, McMaster University, Hamilton, Ontario, published in EPJ E, aims to understand how materials used in flexible electronics behave under stress and strain, particularly, how they wrinkle and buckle.

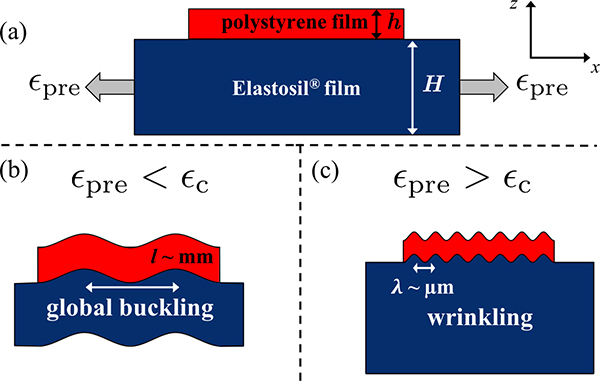

The design of flexible circuits generally involves a thin rigid capping layer – a metallic or polymeric film – placed upon a thick flexible substrate – a soft and stretchable elastomer. Compressing this rigid capping layer can lead to local buckling with a sinusoidal wrinkling pattern that allows its excess surface area to be accommodated by the compressed substrate.

When designing biomedical devices and wearable electronics, mechanical-induced buckling is the most plausible mechanism. Thus, for such applications, it is vital to understand mechanical instabilities and how they depend on the geometry and material properties of the individual layers. The ultimate aim being avoiding a loss of binding between layers and the development of voids.

Niven and his colleagues conducted an experiment to determine the geometrical parameters that dictate how a free-standing bilayer of film transitions into global or local buckling. The experiment also measured the effect of varying characteristics of the capping film and substrate layers such as their relative thickness. Stress was placed on the material – Elastosil sheets – biaxially by shifting the well-adhered layers in different directions, whilst leaving the perpendicular direction of the material fixed.

The result of the team’s experiments was a force balance model that allows researchers to better understand the behaviour of such systems as the thickness ratio between the film layer and the substrate is adjusted, and quantify the amount and nature of wrinkling and buckling in materials that could form the basis of the next generation of electronics.

J.F. Niven, G. Chowdhry, J.S. Sharp, K. Dalnoki-Veress (2020), The emergence of local wrinkling or global buckling in thin freestanding bilayer films, Eur. Phys. J. E 43:20. DOI 10.1140/epje/i2020-11946-y