EPJ E Highlight - Towards tailor-made adhesives

- Details

- Published on 24 January 2014

The inner structure of soft adhesive materials during the debonding process is, for the first time, under scrutiny in the hope of producing new, improved adhesives in the future

Tape, self-adhesive labels, Post-it notes and masking tape all contain soft adhesives. This makes them easy to remove—a process referred to as debonding. French scientists have studied how soft adhesives work in the hope of facilitating the design of more efficient adhesives. Francois Tanguy, a researcher at ESPCI ParisTech, the School of Industrial Physics and Chemistry, in Paris, France, and colleagues have, for the first time, performed a precise analysis of the material deformation and structure during the course of debonding for several model adhesives. Their findings are published in EPJ E. By better understanding the connection between the energy dissipated by the polymeric material with adhesive qualities and its response to traction, they hope to improve models of adhesive performance.

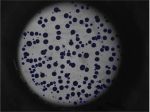

The debonding process itself consists of the emergence of cavities close to the rigid substrate. These grow inside the adhesive material to form a foam-like structure with elongated walls between cavities, called fibrils, until they eventually detach from the substrate completely.

Tanguy and colleagues studied how forces shape cavities during the debonding process. This led them to provide first estimates of the effective elongation and effective stress inside the material’s fibrils. This structural data is then linked to results from previous traction experiments performed on soft adhesives, which mainly consist of nominal stress and strain values.

They used a so-called Probe Tack set up. Namely, they measured the displacement and force applied using a cylindrical probe brought into contact with a substrate and then subsequently detached. They combined these measurements with a visualization of the debonding mechanisms. They then relied on image-processing techniques to analyse the evolution of the debonding geometry of different model materials in detail. Finally, they performed a qualitative comparison of the heterogeneous deformation of the bubbles in space and time with that of homogenous traction tests.

Quantitative analysis of the debonding structure of soft adhesives. F. Tanguy, M. Nicoli, A. Lindner, and C. Creton (2014), European Physical Journal E 37: 3, DOI 10.1140/epje/i2014-14003-8